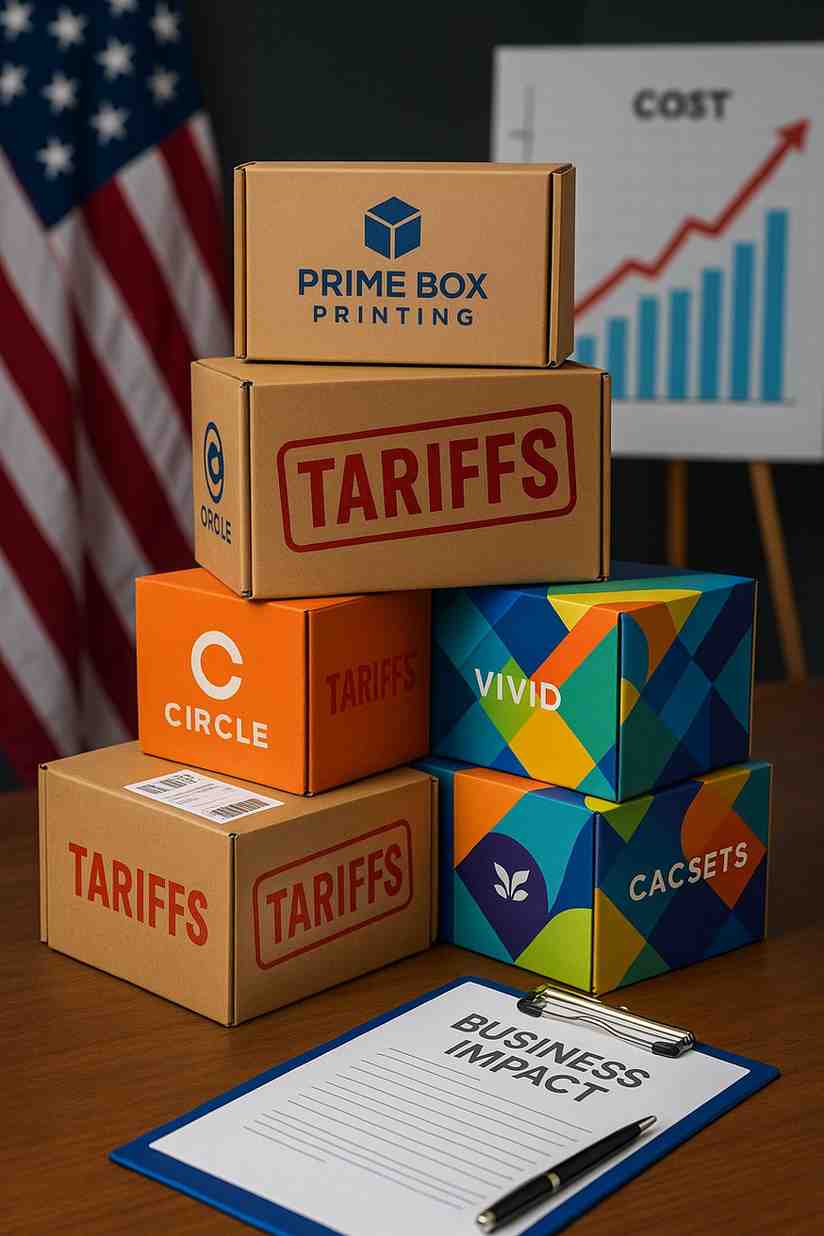

The packaging industry across the United States is navigating a new economic reality. Uncertainty is now the constant. Trade policy is not just a headline it is a daily business decision. Tariffs introduced by the Trump administration continue to shape the cost and availability of materials across all packaging sectors. Eco Packaging Masters are closely tracking these developments to help our clients adapt and stay competitive across Texas and beyond.

Tariffs Have Changed the Landscape

What was once predictable has become volatile. Businesses that rely on paper or plastic packaging are experiencing unexpected price surges. The cost of importing common packaging materials is no longer stable. For many, the impact is immediate. A simple order of paper bags or custom boxes now requires a recalibrated budget. For others, the impact is more long term—affecting supply chains, customer pricing strategies, and delivery timelines.

The most recent updates show total tariffs on all goods from China have reached 145 percent. Tariffs on selected countries started at 10 percent and apply to paper and plastic packaging materials. Though some exemptions exist for countries within the USMCA or outlined in executive orders, many U.S. businesses are already absorbing higher costs.

The Cost of Doing Business Just Went Up

Every packaging decision now carries additional weight. Even a modest 25 percent tariff can transform a one hundred thousand dollar shipment into a one hundred twenty five thousand dollar liability. With each shipment and every unit, the costs compound.

Businesses must now evaluate how to handle this shift. Some will absorb the increases. Others will adjust pricing. Both approaches present risk. Higher prices may trigger shifts in consumer behavior. Buyers may scale back. They may seek more affordable brands. Others may postpone purchasing altogether.

However, this disruption does not only present challenges. It also creates opportunities. Brands and packaging suppliers can collaborate in new ways. Shared goals may lead to better forecasting, improved efficiencies, and long-term partnerships built on transparency and problem solving.

How Tariffs Disrupt the Packaging Supply Chain

The U.S. packaging ecosystem is interconnected. Materials are sourced internationally. Production often occurs across borders. Any disruption to that chain introduces delay, uncertainty, or increased overhead. Supply chains that once functioned like clockwork now face unpredictable bottlenecks.

Cross-border complexity is one of the most pressing issues for brands. A paper bag designed in the U.S. might rely on raw pulp from South America, coatings from Europe, and printing from Canada. If one link is delayed or tariffed, the entire shipment is compromised. What once was a well-oiled system becomes a liability.

We work closely with brands to identify vulnerabilities early. Our network includes trusted domestic and international suppliers. When tariffs shift or policies tighten, we help our clients pivot sourcing to maintain production timelines and preserve margins.

Seeking Alternatives Is Not Always Simple

Businesses considering a supplier switch to avoid tariffs must navigate several obstacles. Testing new materials requires time. Evaluating new vendors involves risk. In many cases, new equipment or machinery may be necessary to support an alternate packaging format.

Moreover, demand is increasing for packaging from tariff-free zones. That demand inflates prices. The effort to dodge one cost increase can lead to another. The answer is not just finding a new supplier. It is finding the right supplier—one that offers transparency, scalability, and consistency.

Through Eco Packaging Master’s established supply relationships, brands gain access to vetted manufacturers who meet both quality and compliance requirements. We offer sourcing flexibility that adapts as trade environments change. Our clients stay ahead while others fall behind.

Trade Uncertainty Creates Business Instability

Tariffs are only one part of the larger trade conflict. International tensions continue to impact how products move across borders. Some suppliers have already withdrawn from U.S. markets entirely. Others have scaled back exports due to instability and policy unpredictability.

These decisions put further strain on U.S. brands that rely on foreign packaging. Planning becomes a challenge. Investment in new lines or products becomes riskier. The market continues to shift without warning.

We take a proactive approach. We identify potential sourcing issues before they occur. If new regions are added to the tariff list, we adjust production and logistics to avoid costly disruptions.

Strategies to Mitigate the Impact of Tariffs

Rather than react to tariffs after they affect the bottom line, brands can take steps now to reduce exposure and build resilience. Here are four proven strategies:

Diversify Suppliers

Spread sourcing across multiple countries. Avoid relying on one region for all packaging needs.

Build Safety Stock

Maintain inventory reserves of essential packaging. This allows time to navigate short-term disruptions without halting operations.

Strengthen Supplier Collaboration

Work with vendors like Eco Packaging Masters to identify cost-effective alternatives and rework procurement strategies in real time.

Increase Agility

Monitor policy shifts. Build operational flexibility that allows fast transitions between suppliers or packaging formats.

These measures are not temporary solutions. They are part of a broader strategy to protect long-term profitability and secure supply chains in an unstable trade climate.

Positioning Your Brand for the Future

The Trump Tariffs may be the current headline, but trade policies can change rapidly. What holds true today may not hold tomorrow. Businesses that build flexible, responsive packaging strategies will thrive no matter what shifts occur.

Eco Packaging Masters supports brands across Texas with custom packaging solutions that adapt to real-world challenges. From sourcing to printing to logistics, we are a strategic partner committed to keeping your supply chain moving and your margins protected.

By preparing for disruption, your business builds strength. By planning for volatility, your brand gains stability. And by choosing partners with insight and reach, you gain the edge in a market that rewards readiness.

To learn more about how to protect your packaging operations from tariff risk reach out to our team. Together, we build smarter strategies and stronger supply chains.