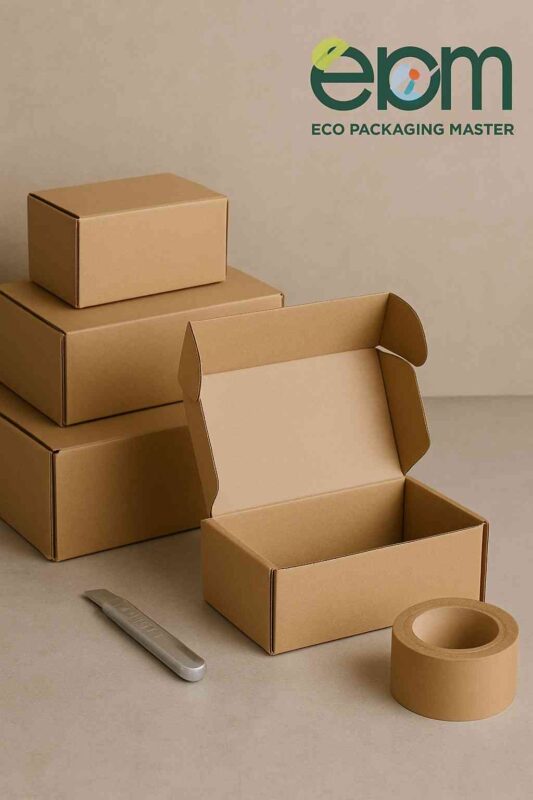

The capability to design shipping boxes exemplifies an essential talent for small business owners along with logistics coordinators. Furthermore packaging products securely allows businesses to use customized solutions that strengthen their brand image. The following guide details the procedure for building custom shipping boxes while focusing on precise dimensions, cost-effective solutions and professional delivery.

Determine the Dimensions

First obtain measurements of the package you need to ship. Use tape measurement to measure length and width and height before adding at least half an inch clearance around the box to protect your products through use of bubble wrap or kraft paper. The constructed box must offer space for the product and adequate padding which serves to minimize cargo displacement.

Choose the Right Material

Corrugated cardboard continues to serve as the best shipping material because it can withstand various conditions in addition to being adaptable. Your choice of protective boards should match the object weight and its susceptibility to damage by utilizing singe-wall, double-wall or triple-wall corrugated sheets. The chosen materials for the box will determine its ability to resist damage from external forces while protecting the product during delivery.

Draft and Cut the Box Layout

Using a ruler, box cutter, and pencil, mark the box layout directly onto the corrugated sheet. A typical design includes:

The base (center rectangle)

Two long side panels

Two short end panels

Four flaps for sealing

A bone folder or blunt edge tool should be used to score the fold lines in order to achieve clean crisp folds. Throughout this stage professionals should pay close attention to precision because it produces both strong aesthetics and uniform structural performance.

Assemble the Box

Perform the folding operation along the marked lines to achieve proper configuration of the box. The final step involves using durable industrial-strength tape along all seams which you should apply inside and outside for complete protection. Enhance protection through reinforcement by using glue as well as tape to secure high-value or fragile items.

Add Internal Protection

Insert the product inside the box first and then wrap it with protective cushioning before you apply the seal. Options include:

Bubble wrap

Molded pulp inserts

Foam padding

Air pillows

During shipping the protective layer ensures avoidance of impact and vibration to prevent product damage.

Seal and Label the Box

Use heavy-duty tape to create a thorough closure of the package’s flaps. All package edges require strong reinforcement before sending packages that travel either long distances or internationally. Place clear shipping markings on the box which contain recipient details along with shipping information and required labels or barcodes. Place proper warning labels on shipping cartons whenever materials show signs of fragility in order to inform logistics personnel.

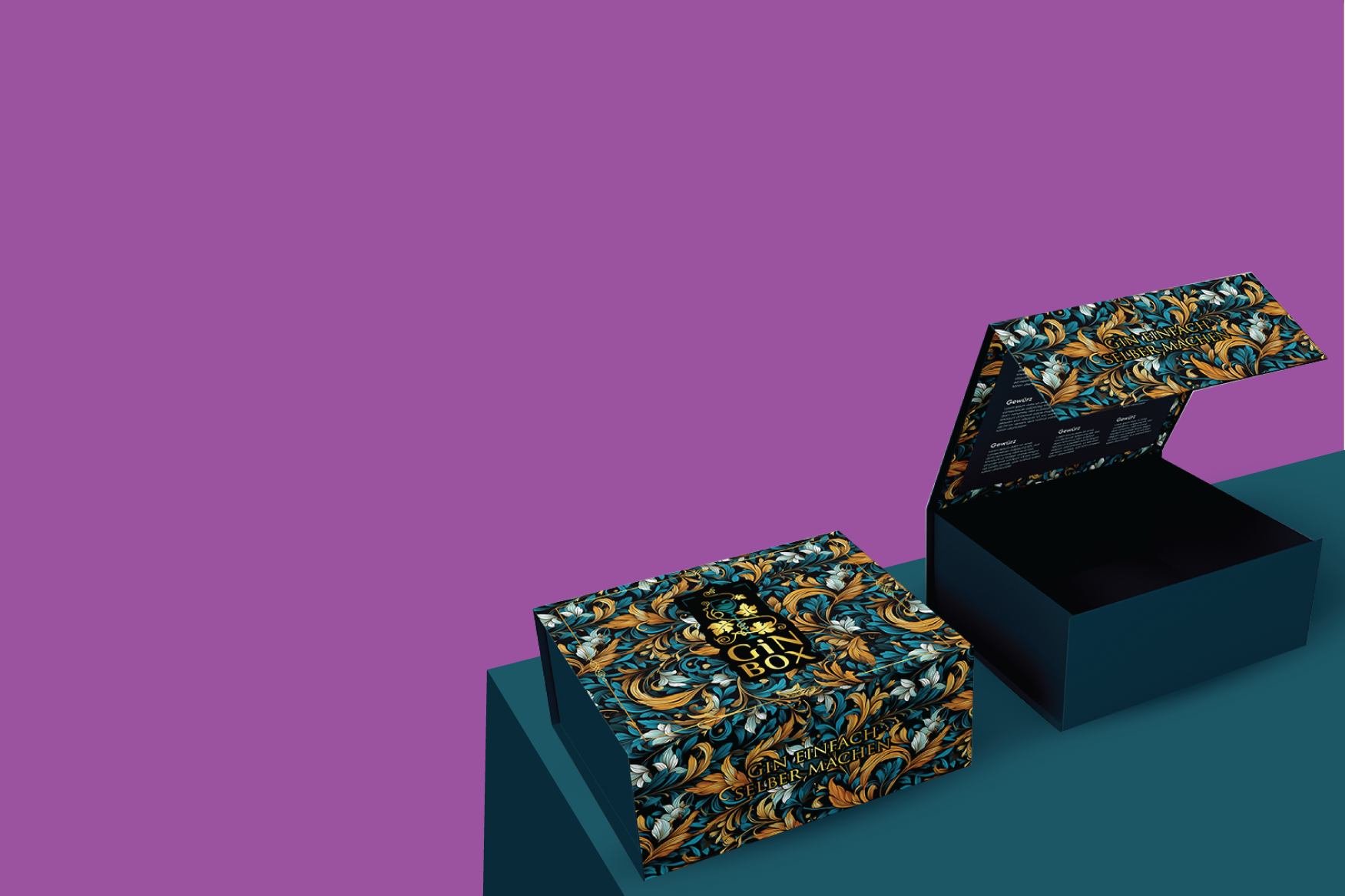

Optional: Add Branding Elements

You should customize your shipment by adding custom printed labels with your business logo and branded packing tape when the package represents your company. Specially chosen elements help brands enhance visibility and express both professionalism and care when processing packages.

In the Final

Launching a custom shipping box beyond serving functional purposes represents an essential business approach to safeguard your products while demonstrating brand professionalism. Businesses can create customized packaging solutions which satisfy logistical requirements through the mentioned steps to enhance customer satisfaction.